Green Steel Companies: 7 Powerful Innovations Reviving US Steelmaking

Green Steel US Revival are redefining what steel production could look like in the future. Once associated with massive blast furnaces and carbon-heavy emissions, steelmaking is now being reimagined with cutting-edge technology, renewable energy, and ambitious startups determined to transform the industry.

Across the country, companies like Boston Metal and Electra are taking bold steps to make steel production cleaner, more efficient, and less dependent on fossil fuels. This shift is not just about business, it’s about addressing the global climate crisis while securing the future of American manufacturing.

Why Green Steel Companies Matter

Steel is one of the most widely used materials in the world, essential for everything from cars to skyscrapers. Yet, the traditional process of making steel through blast furnaces is incredibly carbon-intensive. According to the International Energy Agency (IEA), steel production contributes nearly 11% of global carbon emissions, comparable to all the world’s cars and vans combined.

That’s why green steel companies are so important. By rethinking the way iron and steel are produced, these innovators could slash emissions and help the US lead in sustainable industrial technology.

Boston Metal: A Pioneer in Electric Steelmaking

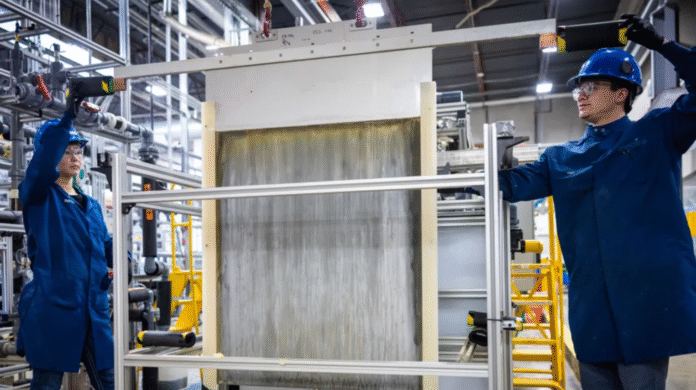

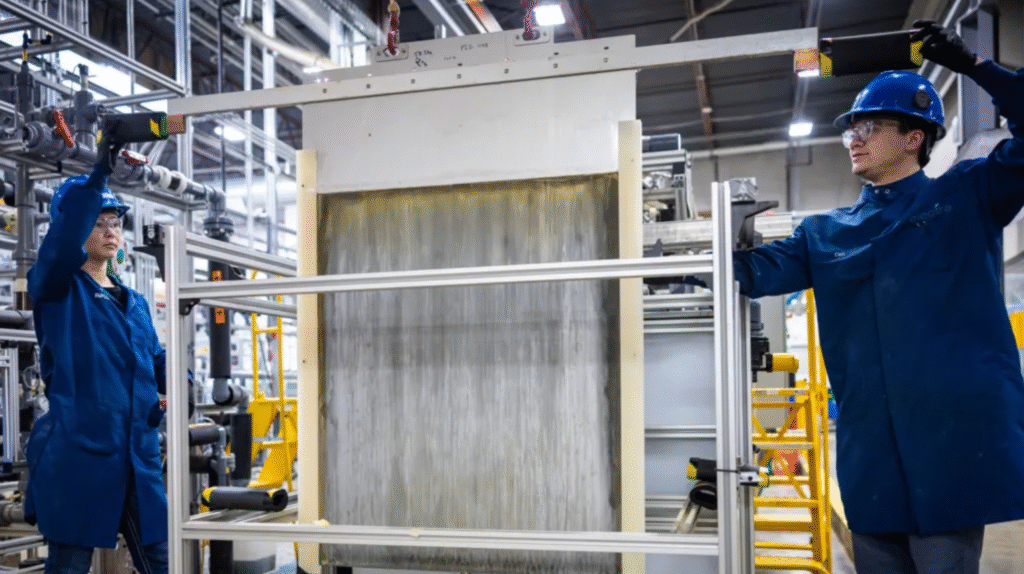

Boston Metal, based in Woburn, Massachusetts, is at the forefront of the green steel revolution. Unlike traditional methods that rely on burning coal, the company has developed a process that uses electricity to extract iron from ore.

The method involves dissolving iron ore in an electrolyte and then heating it to 1,600°C. Through electrolysis, impurities separate, leaving behind pure molten iron. This innovation means cleaner production without the reliance on fossil fuels.

Boston Metal plans to launch its first demonstration-scale plant by 2028. If successful, it could drastically reduce emissions and set the standard for future Green Steel US Revival worldwide.

Electra: Reinventing Iron Production at Low Temperatures

Another promising player in the sector is Electra, headquartered in Colorado. Unlike Boston Metal’s high-temperature process, Electra works at just 60–100°C.

Here’s how it works: iron ore is dissolved in an acidic solution, and then electricity is used to deposit iron onto plates. This is similar to the electrochemical processes used for metals like copper and zinc.

While the initial costs are higher, Electra’s method offers enormous potential. Its demonstration plant, capable of producing 500 tonnes of iron annually, is set to open soon.

Challenges Facing Green Steel Companies

Despite their potential, green steel companies face major hurdles. Scaling up new technology requires heavy investment, stable policy support, and affordable renewable energy.

Some steel giants, like Cleveland-Cliffs, have already backed away from ambitious hydrogen-powered projects due to cost concerns. Without sustained support, smaller startups risk being overshadowed by entrenched industry players.

Moreover, the reliance on scrap steel for electric arc furnaces creates limitations. In countries like China, low scrap availability has slowed the adoption of greener methods.

The Role of Renewable Energy

Renewable energy is the backbone of the green steel revolution. Both Boston Metal and Electra rely on clean electricity to power their processes. Without affordable wind, solar, and hydropower, their vision of zero-emission steel will be hard to achieve.

Industry experts, like Simon Nicholas from the Institute for Energy Economics and Financial Analysis (IEEFA), warn that time is running out. “We’re running short of time for addressing carbon emissions,” he said, highlighting the urgency for scaling these innovations.

US Politics and Green Steel US Revival

Government policy plays a critical role in the survival of green steel companies. Tariffs on imported steel may protect domestic producers but also risk raising costs for US customers. At the same time, inconsistent support for renewable energy complicates efforts to decarbonize steelmaking.

Still, US firms are ahead compared to other nations, thanks to the widespread use of electric arc furnaces and the determination of startups pushing for cleaner methods.

The Bigger Picture: Can Green Steel US Revival Succeed?

The rise of green steel companies represents more than just technological progress, it’s about reshaping an entire industry. With carbon neutrality goals looming, demand for low-emission steel is expected to soar. Automakers, construction firms, and even governments are now looking to secure greener supply chains.

If startups like Boston Metal and Electra can scale successfully, they could not only reduce global emissions but also revive US steelmaking as a world leader in sustainable innovation.

The question remains: will investment, policy, and global demand align fast enough for these green steel pioneers to succeed?